PETYLON® (PET + NYLON)

PETYLON is a new material by mixing post consumed PET (bottles) and waste Nylon (clothes). PETYLON resins keep the properties of PET – dimensional stability, resistance to impact, moisture, alcohols and solvents and the properties of NYLON – tensile strength, elasticity, and abrasion resistance. MEPPS enables to keep the properties of post consumed PET and waste NYLON. MEPPS combines two different materials with no use of any chemicals or additives. Depending upon how it is processed, it is possible to make various kind of PETYLON. PETYLON can be substitute for PP, PPE, HEPE and other resins.

Benefits of post-consumed PET bottles

- The more recycling more PET water bottle, the lower amount of waste that contributes to landfills and ending up into oceans.

- Lower greenhouse gas mission. The process of recycling PET bottles uses less water and energy than the process of virgin PET , therefore reducing greenhouse gases – carbon dioxide, carbon and even dust. The reducing greenhouse gases also lower the pollution rates. Recycled PET has a lower carbon footprint than virgin PET.

- Reduces demands for raw materials

- Save on Energy. Recycling PET bottle needs less power than process virgin materials. It reduces the amount of fossil fuels to be used. Reducing fossil fuels is one of advantages of recycling PET bottles.

- The cost of recycling PET bottle may less than disposal of waste PET bottles if consider economic and environment effects.

- CO2 decrease

- Save WATER – The process of making PETYLON does not need water. GAVEN SYSTEM does not use any chemical in the process of making PETYLON.

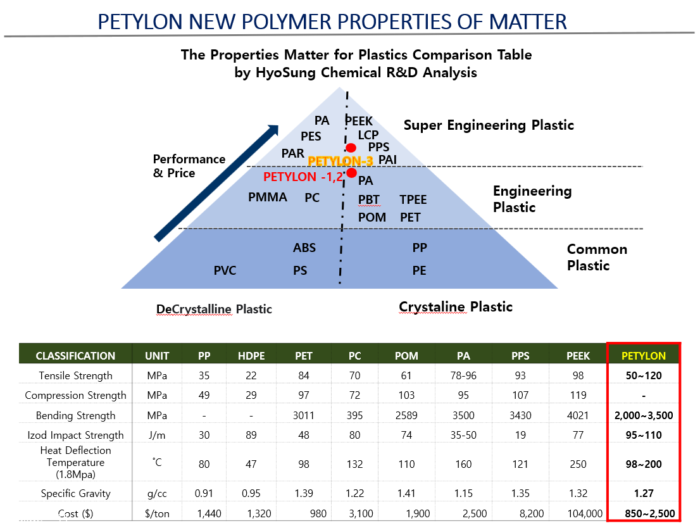

The table shows the material properties of PETYLON. PETYLON is a Resin by compositing two materials. So the material properties can be controlled by blending of materials and it enables to make Resin what users want.